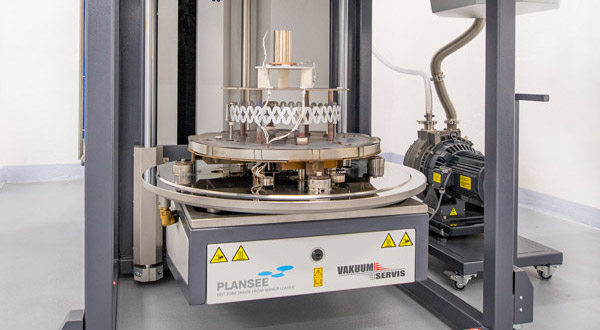

Vacuum Furnace - HVF 4560

Metallic Technologies s.r.o.

We invite you to visit our headquarters at Bačetín 121, where you will have a unique opportunity to see our demonstration vacuum furnace for capillary brazing. Come and discover how this technology takes the quality and reliability of joints to a whole new level. We will be happy to explain the furnace's operating principles and show you how this innovation can support growth and efficiency in your industry.

We look forward to welcoming you in Bačetín!

What do our vacuum furnaces offer?

Our vacuum furnaces are designed for maximum quality, efficiency, and reliability in brazing and other heat treatment processes. Thanks to advanced vacuum technology, they minimize oxidation, ensure clean and homogeneous joints, and reduce the need for additional processing. They offer precise temperature control, rapid heating, and efficient cooling, enabling optimal results even with the most sensitive materials. An ideal solution for electronics, the automotive industry, electron microscopy, and other sectors requiring high-quality joints without compromise.

Easy Handling

Thanks to the lifting system, products can be loaded into the vacuum furnace chamber quickly and efficiently.

Spacious Working Chamber

We offer working chamber sizes tailored to your requirements, ranging from 100 mm to 1 000 mm in both diameter and height.

High-Quality Software

Each furnace in our range is equipped with high-quality process monitoring software, ensuring maximum quality and safety. Preconfigured capillary brazing process profiles and exports of individual brazing cycles for product traceability are standard features.

High-Quality Components

Each manufacturing process, most of which takes place in our factory, is carefully monitored and controlled at every production stage. We also carefully select our suppliers, including Vakuum servis s.r.o. and Plansee SE.

Parameters of vacuum furnace HVF 4560

| Working Temperatures | |

| Operating Temperatures | 20 - 1 300 °C |

| Working Chamber Dimensions | |

| Diameter | 450 mm |

| Height | 650 mm |

| Load Weight | 0,5 - 50 kg |

| Working Pressures | |

| Low Vacuum | 1×10-3 mbar |

| High Vacuum | 1×10-7 mbar |

| Inert Gas | 1 mbar – 1×10-4 mbar |

| Machine Dimensions | |

| Height | 2 600 mm |

| Width | 1 850 mm |

| Depth | 2 300 mm |

| Dimensions of HVF 4560 in the Photo | |

| Other Parameters | |

| Pumping System | Turbomolecular / Dry Auxiliary Pumping System |

| Cooling | Water Cooling |

| Machine Control | Windows 10 / PLC Siemens / Industrial Touchscreen Monitor |

| Trolley Movement | Servo Drive / Lift 800 mm |

| Chamber Observation Port | CF40 Port |

| Heating System | 3 Independent Heating Zones |

| Temperature Measurement | Thermocouples Type K / S |

| Machine Weight | 3 200 kg |

| Power Consumption | 65 kW |

Solid connections thanks to capillary metal soldering

The vacuum furnace for capillary soldering is a special device used in the production of high-quality and reliable joints, especially in the electronics and automotive industries. It works on the principle of heating materials in a low pressure (vacuum) environment, which minimizes oxidation and improves the purity of the solder joint. Thanks to the capillary effect, the solder is optimally spread and penetrates all necessary areas, ensuring a solid, homogeneous joint. This method is particularly useful for sensitive components where high joint quality is required.