About us Metallic Technologies Ltd.

We are Czech engineering company focusing on production in the field of vacuum technology, automation, automotive and metal production.

Our own products are vacuum furnaces, vacuum chambers and vacuum components, which we supply to our business partners in the Czech Republic and abroad. An important part of our production is also production according to customer´s documentation.

We have our own 3D structural design department and team of experienced staff in the technological preparation of production and in the production itself.

ISO 9001 certification

We continuously maintain and develop the established ISO 9001 certification. We strive to be environmentally friendly.

Headquarters Metallic Technologies Ltd.

What do we offer?

Design and development

We have our own development and design department, whose main activity is to prepare high-quality drawings for the subsequent production of parts or entire devices.

We are able to design and manufacture equipment to meet the customer’s requirements to the maximum extent and to meet the requirements for the safest possible operation, with a view to future operations or seamless integration into the production line.

3D design, development of parts and equipment

The development is based on many years of our own experience in design and construction, which are fully utilizes in the processing of our customers’ assignments. Our engineers prepare a design (study) of individual parts or units. After approval of the design by the customer, they will design the entire device in 3D CAD software SolidWorks.

It is optimal to inspect the customer’s production facilities, to determine the expected location of the new equipment, or which downstream technology the equipment will work with. This information is used by designers and technologists to create the right idea of the purpose of the machinery in order to achieve maximum understanding of the customer’s idea.

The result of the designer’s work is that the part or whole device is designed completely in a 3D environment, where there is a clear idea of how the part, or the device will look like. During the design process possible clashes with other parts or inaccuracies are revealed or eliminated at early stage. The surrounding environment of the new device is also included in the design, so that any possible connections to downstream technologies is also addressed.

In the final stage drawings of individual parts, sub-assemblies and main assemblies are creates and then manufactured.

Machining

We are equipped with several machine tools that are CNC controlled or operate older machine tools with conventional technology.

Most of the parts of our productions are machined by us.

We are able to provide machining of parts even with size 2500×1500×3000 mm. We place great emphasis on the overall quality of processing, including the final finish with required surface roughness. If it is necessary to use other machines for machining parts (for larger workpiece dimensions or mode axes are needed), we use our reliable cooperation partners.

We use the following facilities:

- CNC Milling machine: FEELER VMP50-A, working area x-1300 / y-600 / z-610

- CNC Lathe: STYLE 510, work area Ø510, Ø300 x-1350

- Lathe: TOS SV18-RA, TOS SV18-RD

- Drilling: column drill VS-32, Heltos VS32 with speed control, radial drill VR-4

- Rounding: Metalkraft- RBM 1050-30 E (hardened cylinders)

- Threading: ROSCAMAT - MOSQUITO 300 V

- Cutting: band saws from Bomar and Pilana

- Bale box: internal dimensions 1800 × 1200 mm

- Grinding and polishing: Suhner flexible shaft grinder

Photo gallery

Welding

We provide professional welding of various materials – stainless steel, steel, aluminium, or its alloys. We have equipment for MIG, MAG and TIG welding.

Welding of steel, aluminium, and stainless steel

- We weld steel covers, machine parts, steel structures, machine flames and other products

- We weld vacuum chambers, vacuum parts, vacuum piping, machine parts and other products from stainless steel

The experience of our welders is always directly related to the final quality of our products. We are also able to cope with the requirements for the tight tolerances of the weldments.

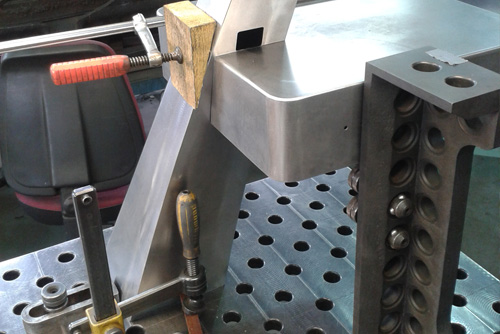

We own five welding tables that have holes drilled horizontally and vertically on the work plate for mounting various accessories. These welding table guarantee high quality weldments and productivity of the welding process. The welding tables can be joined together to create the required size with perfectly flat surface even for large products.

Sizes of individual tables:

- S1: 3000×1500×200

- S2: 1500×1000×200

- S2: 1500×1000×200

- S4: 1500×800

- S5: 2000×1000

Helium Leak finder

Especially when welding vacuum parts, the quality of the welds is very important. We carry out a 100% leak check of all welds using the HLT 560 helium leak finder from Pfeiffer Vacuum.

Photo gallery

Installation

The assembly of manufactured equipment is carried out by experienced workers with quality equipment. Assembly work is carried out in suitable premises with regard to the required product quality.

We can also handle large or heavy parts, we have cranes with capacity of 5t and 8t, forklifts 4t and 1,5t. We are also equipped for assemblies with a requirement for cleaner environment.

When assembling the equipment, we ensure that all assembled assemblies are carefully executed. We place a great emphasis on the installation of cable routes to minimize the risk of damage to cables from traffic or unprofessional operator intervention. All connection made are marked with labels and appropriate descriptions.

We are able to provide complete assembly of the entire device or its subassemblies, pneumatic ad hydraulic assemblies and wiring.

The resulting design shall comply with the relevant applicable standards and meet ergonomic and safety requirements.

The company has a helium leak finder HLT 560 from Pfeiffer Vacuum. With this device we check all welded vacuum chambers that are manufactured in the company. The helium test is also carried out on the assembly of complete vacuum systems and vacuum components where applicable.

Photo gallery

Service

We guarantee warranty and post-warranty service for the entire lifetime of the equipment and machines manufactured and installed by the company.

In agreement with the customer, we carry out preventive service inspections to reduce the risk of breakdowns.

The following is provided as part of the service:

- Installation – assembly, commissioning of machines

- Operator training – familiarization of the operator with the use and adjustment of the machine

- Repair and adjustment of machines – manufactured and installed by the company

- Preventive inspections – to prevent problems and reduce the cost of dealing with them

- Consultancy – for warranty and post-warranty repairs, to solve any problems as quickly as possible